Investigating Low-Volume Approaches to Vineyard Cooling

High heat can damage both fruit and foliage. A group in Napa is investigating alternatives to overhead impact sprinklers.

By Mark Greenspan

The following has been reprinted from and article in Wine Business Monthly 2009. Read the original article here.

In last month’s column I indicated that a survey of Sonoma/Mendocino growers revealed that use of overhead sprinklers to cool fruit during hot weather periods is a common practice in warmer growing regions of the North Coast. The downside of overhead sprinklers is that they are tremendous users of water, and suck up water at the most demanding time of day. We don’t know if the dry spring rainfall patterns experienced in 2007 and 2008 were a harbinger of things to come, but water conservation can be expected to be on the minds of our industry for now and for good.

Why cool vines?

The moderate climate enjoyed by the North Coast is frequently interrupted by periods of high heat. The heat waves can reach well into the 100’s, sometimes reaching above 115°F. While foliage is sensitive to heat, it has the advantage of transpiration, which is a natural way in which leaves cool themselves by evaporating water from their interiors. On the other hand, fruit lack active stomatal pores and cannot cool themselves as effectively as leaves. Pigmented fruit will absorb additional energy from the sun, as it reflects less sunlight energy than light-skinned grapes. Outer berries, exposed to direct sunlight, may reach 15°F above ambient temperature. High temperatures are detrimental to fruit and wine quality. Apart from the obvious consequences, such as sunburn, shrivel and loss of pigment, the heat may also lead to changes in flavor, aroma and mouthfeel compounds and precursors. Regardless of subtleties, it is always heartbreaking to tend a vineyard all year only to have a mid- or late-season heat wave shrivel fruit, creating overly cooked, pruney and raisiny flavors in the wines. Not to mention the yield losses…

Napa vineyard cooling project

A group in Napa Valley is exploring the use of low-volume misting spray heads as an alternative to the high-volume traditional impact rotor sprinkler. The project has been largely supported by Beaulieu Vineyard (BV) and was conducted in one of their vineyards in the Oakville area. With support from numerous additional donors, this project used numerous temperature sensors within the canopies and within fruit clusters. The electronic temperature data from each sensor was automatically logged so that the information could be downloaded at the end of the trial for analysis. An ambient temperature sensor was connected to a digital readout to provide an indication of current conditions (without cooling) so that system startup and shutdown could be determined. BV uses Walsh Vineyards Management to manage the vineyard and they played a key role in the planning and execution of the project, in addition to support from Pacific Geodata and VineView Imaging companies. My company, Advanced Viticulture, has been assisting in the data interpretation for the project.

The misters were supplied by Jain Irrigation, who modified one of their pressure-compensating emitters to produce a fine mist, rather than a drip or a coarse spray output. The idea here was to have the mist evaporate in mid-air, rather than to coat the foliage with water. The evaporation of water removes heat energy from the air, which is the desired effect. The aerial evaporation was somewhat successful, though the over-vine cooling did tend to wet the fruit and foliage. Similarly, the under-vine cooling wetted the soil below the vines. The intention was not to irrigate the vines with the cooling system, but this did occur to some extent in both systems. There was a small water stream emanating from the emitters, which drizzled down and tended to provide some irrigation to the vines, which was not a desired outcome. The manufacturer has since told us that they can improve the design so that the dripping does not occur.

The project falls somewhere between a casual grower “Side A – Side B” type of trial and a real scientific experiment. Practicality and cost made replicated field plots impossible. Nevertheless, the treatments were made thoughtfully and the temperature measurements made with replication. The vineyard block is Cabernet Sauvignon on O39-16 on a VSP trellis oriented east-west. There were three treatments each of which occupied 14 rows, with temperature monitored only within the center of each plot, so that advection effects from neighboring plots could be eliminated as much as possible. The control was un-cooled, regardless of ambient temperature. There was an “under-vine cooling” treatment, where the misters were installed below the cordon, just above the drip hose. This provided a mist pattern that remained low to the ground and did not wet the foliage or the fruit. A third treatment was an “over-vine cooling” treatment. Similar to a micro-sprinkler installation, spaghetti tube risers were raised about a foot above the canopy and terminated in the misting heads. The output rate of the mister systems were about the same as for the vineyard’s drip system, at just short of 1 gallon per minute per device, spaced out at one device per vine (compared to two half GPH emitters per vine).

The system was turned on whenever the temperature reached 93°F. This was chosen because it was determined that the intent was to have cooling engaged when temperatures rose to 95°F. It was discovered that about 30 minutes elapsed between when the system turned-on and the effective cooling was achieved, which roughly equated to 2°F of temperature rise, as was determined from plots of diurnal temperature curves without cooling. In retrospect, this was a conservative starting point, but was highly impactful at reducing some of the severe temperatures experienced in late August and early September. The system was turned off when the temperatures fell below the 95°F threshold. Additionally, the system was not activated if the 93°F threshold was attained late in the afternoon, at which time temperatures begin to cool.

Initially, heat suppression during both pre- and post-veraison periods of berry growth were planned. However, because of the small, but significant, amount of water dripped onto the ground, it was elected not to use the system prior to veraison, since the vineyard was not being irrigated at that time.

Measured cooling effect

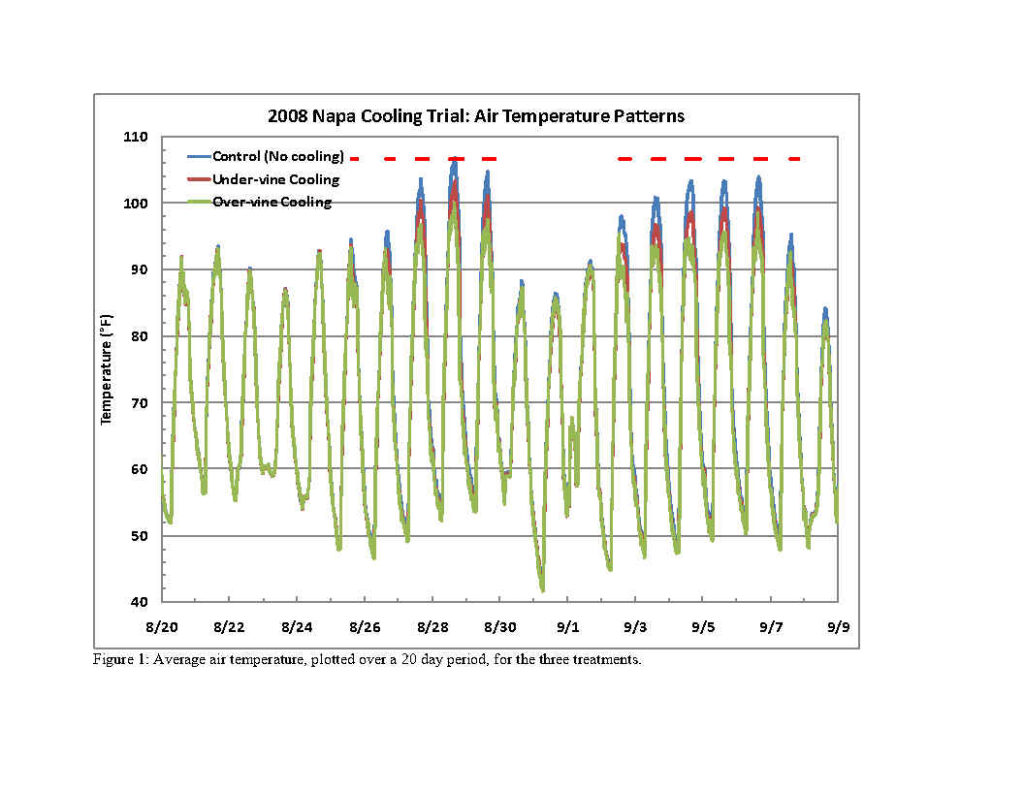

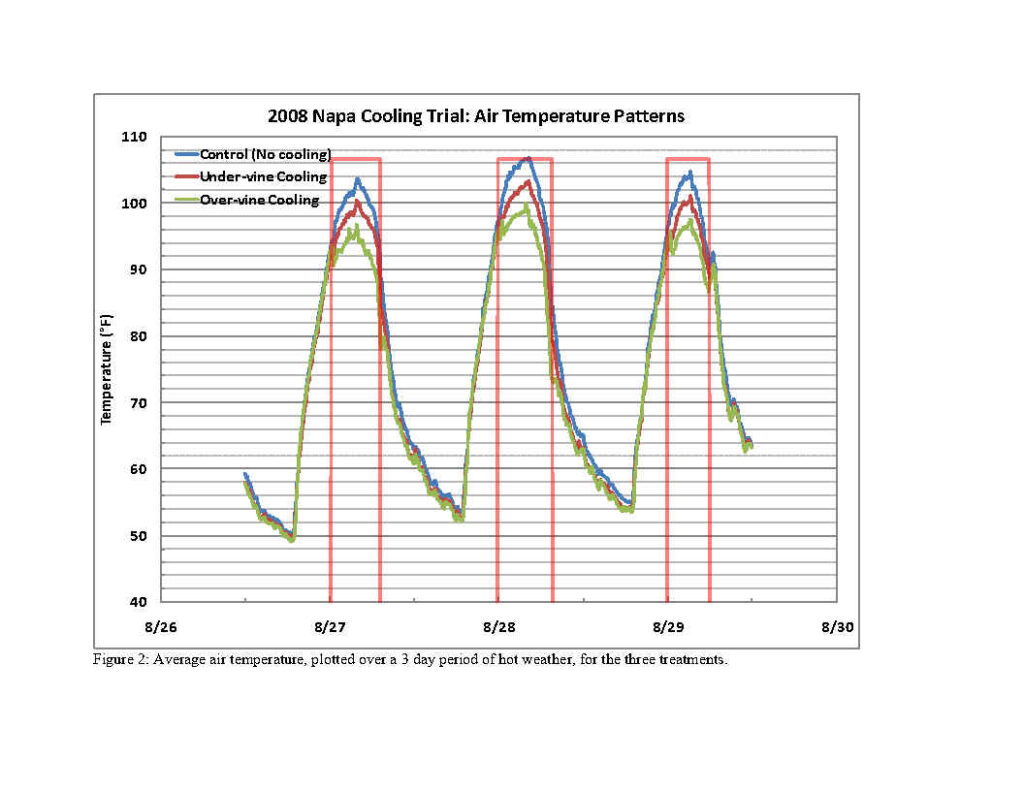

There was a pronounced and easily noticeable reduction in ambient air temperature with both cooling systems. Figure 1 shows a time series of continuous temperature, averaged over all air temperature sensors for each of the three treatments. The red bars indicate when the system was active. It is clear to see that the temperatures of the cooled treatments were far lower when the system was activated on the hot days. It is also clear that the over-vine cooling treatment created more of a cooling effect on the ambient air than did the under-vine cooling. Figure 2 shows a close-up of three consecutive days of heat, and illustrates how quickly the cooling effect is achieved after the system is turned on. In this example the under-vine cooling seemed to reduce air temperature by about 4°F while the over-vine cooling reduced air temperature by about 7°F while the system was in operation. Despite the temperature peaking at about 107°F on August 28th, the air temperature of the over-vine treatment did not exceed 100°F. The cooling effect on the air was quite noticeable when standing out in the vineyard on a hot day.

Cluster temperatures were measured with temperature sensors installed in the interior of clusters. Since Cabernet Sauvignon has a fairly loose cluster, the sheltering of the sensors was not perfect, but decent enough to provide comparisons among the treatments. Figure 3 shows the same three day time sequence as Figure 2, but plots the cluster temperatures over time. Depression of cluster temperature was even more pronounced than that of air temperature. For instance, cluster temperature of the uncooled control, reached 109°F on August 28th, while the clusters in the under-vine treatment were about 7°F lower. But, quite dramatically, clusters in the over-vine treatment were about 13°F lower than the control treatment! Keep in mind that these were cluster interiors – outer berry temperature suppression may have been even greater.

Average temperature differentials for air temperatures during the center hour of the cooling cycles at foliage height and cordon height, as well as for clusters appears in Figure 4. Overall, the over-canopy cooling system was able to cool about twice as much as the below-canopy system. On average, clusters were cooled about 5 degrees with the under-vine system and about 12 degrees with the over-vine system.

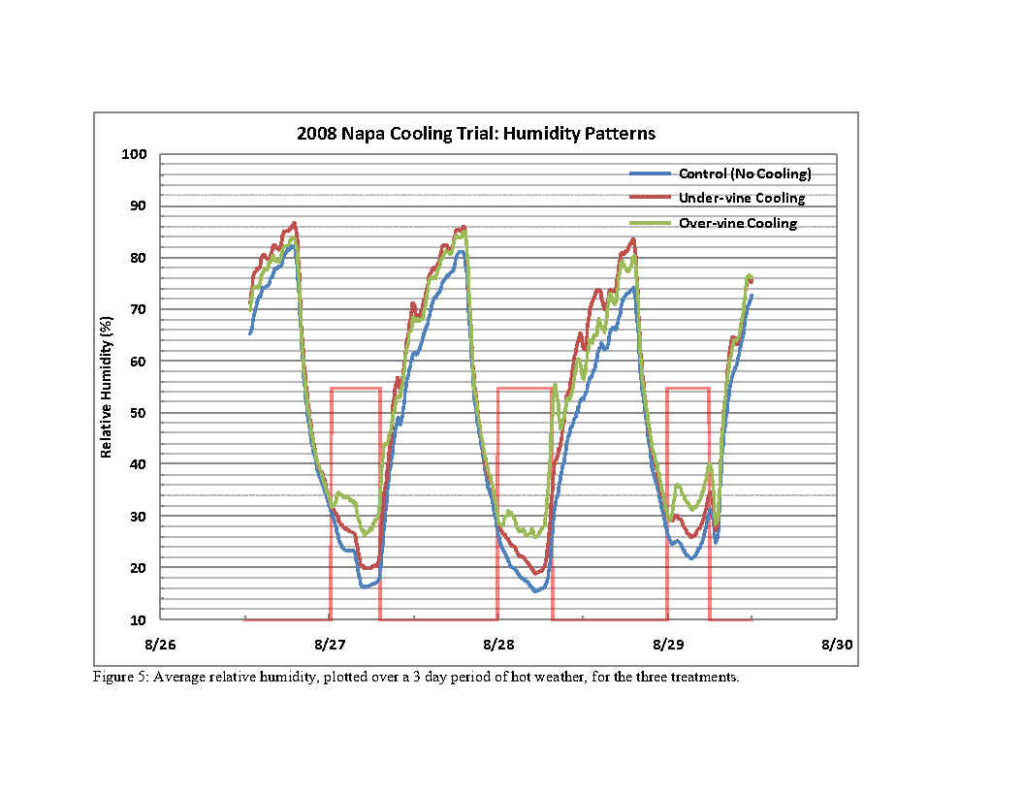

One may jump to the conclusion that the over-vine system is the way to go, and in very hot climates that may well be the case. But the over-vine system was observed to wet the foliage as well as some of the clusters. White mineral deposits left from the applied mist were found on the leaves in that treatment. Also consider the humidity impact of each treatment, an example of which appears in Figure 5. Note that the relative humidity level was increased by about 4% humidity for the under-vine treatment and increased by about10% humidity in the over-vine treatment. The humidity difference persisted into the night. While Cabernet Sauvignon is not rot-prone, the higher humidity of vineyards under this type of cooling system may create a disease problem with tighter-clustered, thinner-skinned varieties.

Fruit composition and integrity

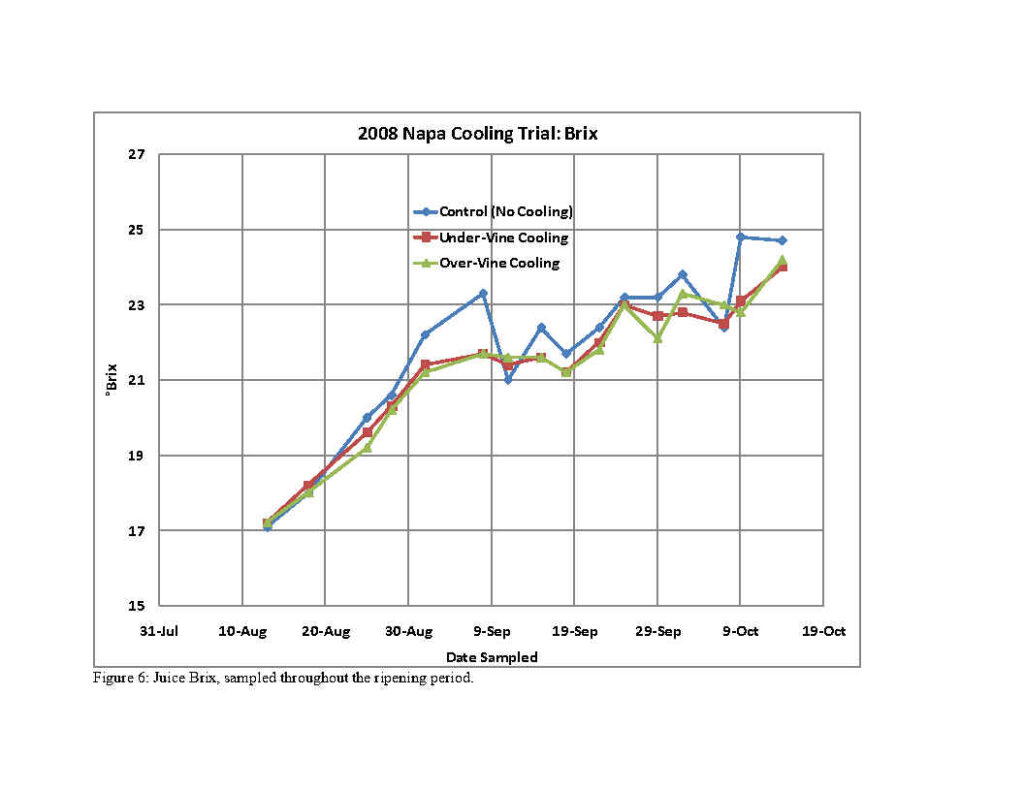

While it is interesting to look at the microclimatic effects of these cooling treatments, the bottom line is its effect on fruit and wine quality. Wines are currently being made at BV using fruit from each of the vineyard treatments. Those wines will surely provide the best indication of whether these cooling treatments were beneficial or detrimental to the primary thing that really matters: the end product. In the meantime, it is interesting to look at some of the fruit composition data that was collected in this trial. For instance, Brix (Figure 6) was generally highest in the uncooled control treatment. It also tended to be more variable over time. This might have been due to the greater amount of shriveled fruit in that treatment, and sampling of fruit could have easily captured varying amounts of this shrivel in the sample each time. A visual inspection revealed considerable fruit shriveling in the control treatment, while fruit in both of the cooling treatments appeared to be generally free of shrivel[1].

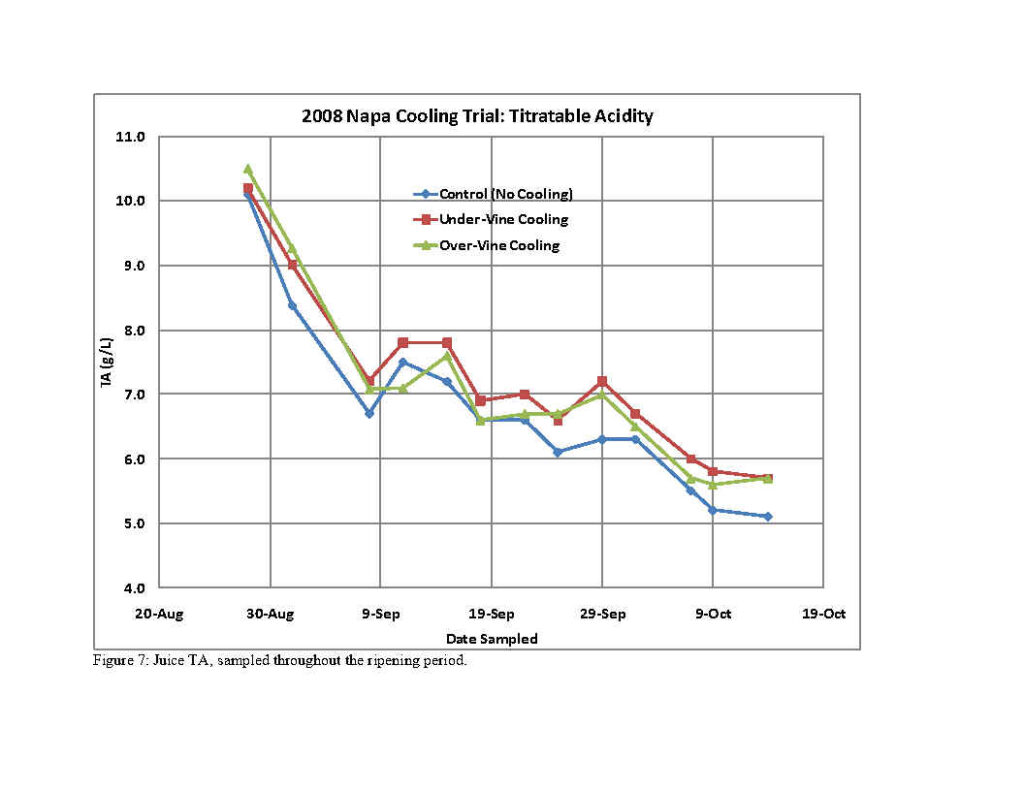

Fruit pH (not shown) did not differ by much across the treatments, though it was slightly higher in the control treatment by the time of harvest. Acidity, on the other hand, was considerably different in the cooled treatments. The uncooled control treatment had consistently lower titratable acidity (TA, Figure 7) than the other two treatments throughout the ripening period. This was undoubtedly due to the higher fruit temperatures during the peak heat episodes, which must have caused berry metabolism to increase dramatically. TA tended to be slightly higher in the under-vine cooling treatment, though this did not hold true for the final harvest sample.

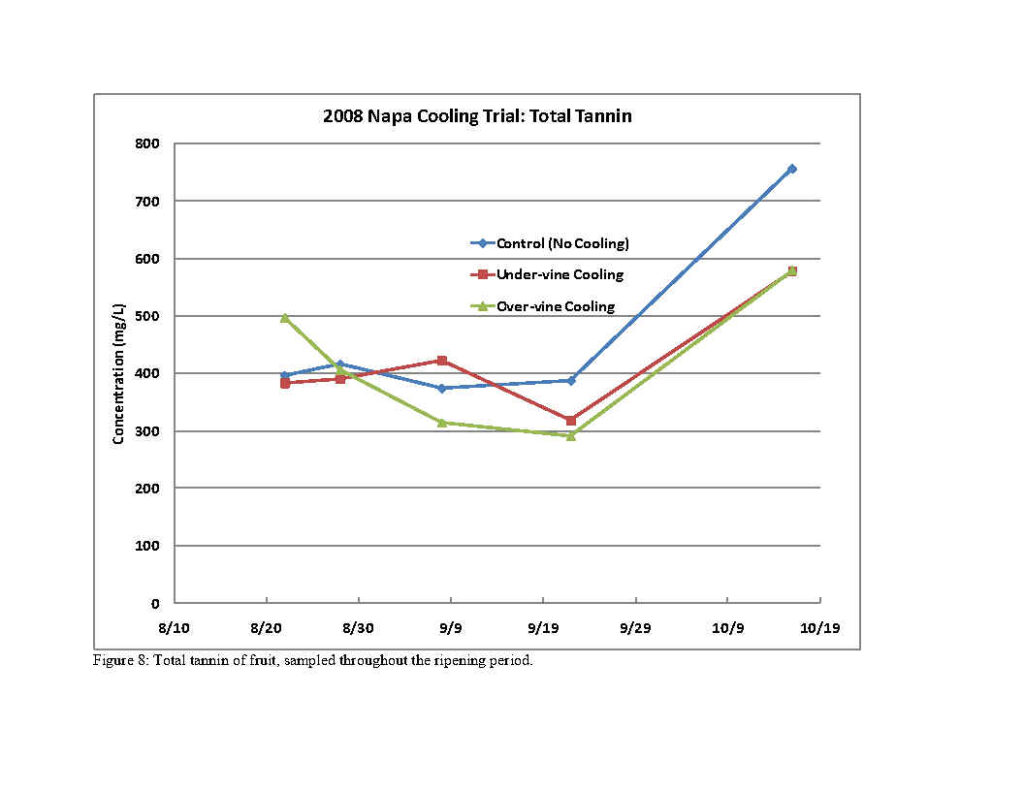

Perhaps a bit disheartening was the observation of higher tannin concentrations in fruit from the control treatment (Figure 8) relative to that of the cooled treatments. Additionally, polymeric anthocyanin was in highest concentration in the control treatment, though total anthocyanin levels were nearly identical among the treatments by the time of harvest (data not shown). While moisture content of the fruit was lowest in the control treatment, the difference in moisture content alone was not sufficient to explain the higher concentrations of tannin and polymerized anthocyanin pigments in the uncooled fruit.

Does this mean that the cooling treatments, while effective, did not benefit wine quality? It is difficult to believe that the level of shriveling in the uncooled fruit would lead to superior wine than the largely sound fruit in either of the cooled treatments. While the fruit composition levels do not seem to support higher potential wine quality in the cooled fruit, there are numerous other variables at play during and following vinification of the fruit. So, until the finished wines are revealed and evaluated, we will not know for whether either of the cooling treatments show promise for wine quality improvements. Nevertheless, the preliminary results of this trial indicate the cooling power effectiveness of a system that uses a tiny fraction of the water of a conventional impact sprinkler system. Sounds pretty cool to me!

[1] For a video of the trial, including some visual observations of fruit integrity, view the video below.